RMGT 790

Max paper size 788 mm

Max thickness 0.8 mm

The brand new RMGT 790

Ultra-fast starts for greater productivity

in the printing of various short-run jobs

Ultra-fast starts for greater productivity

in the printing of various short-run jobs

The new RMGT 790

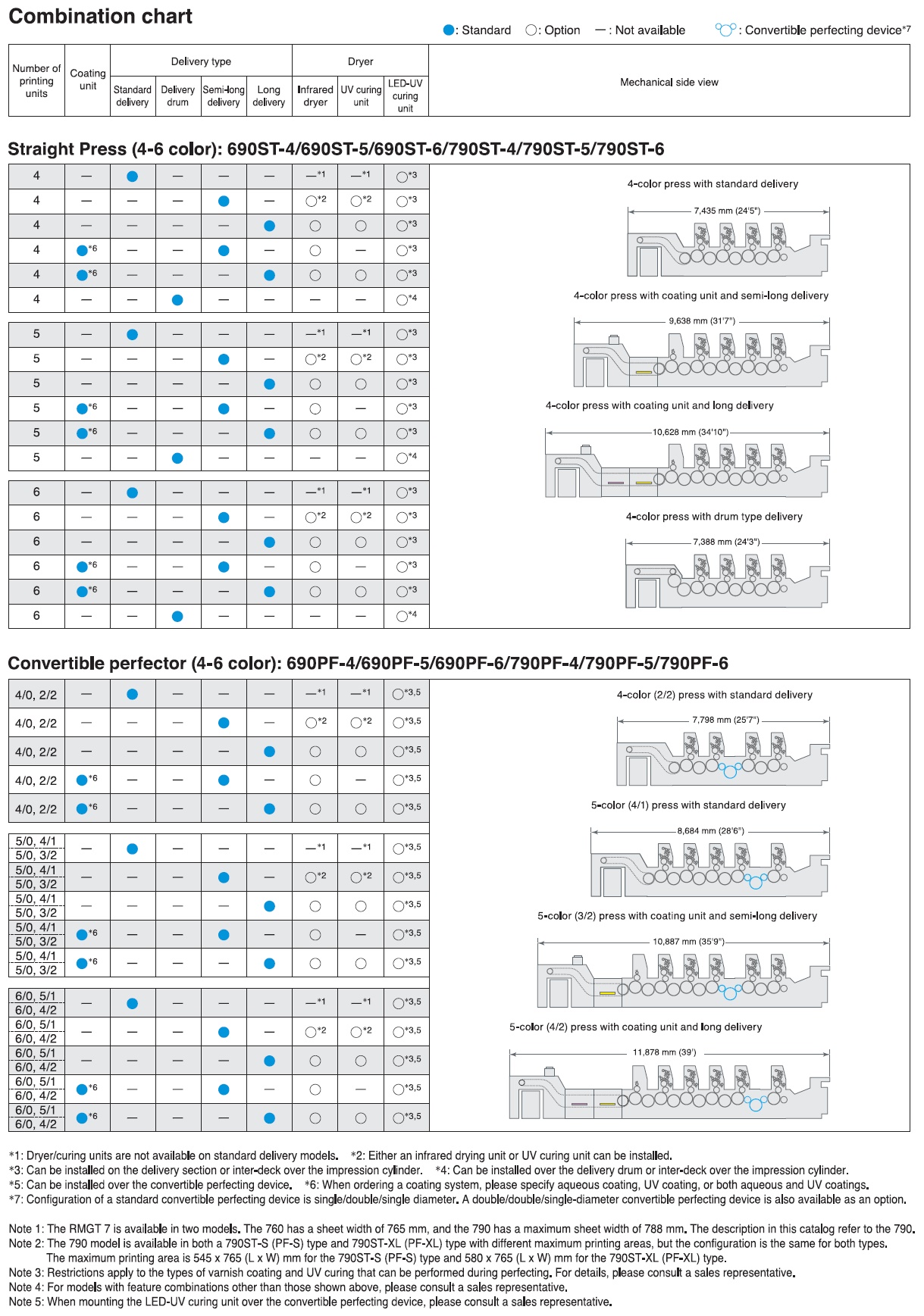

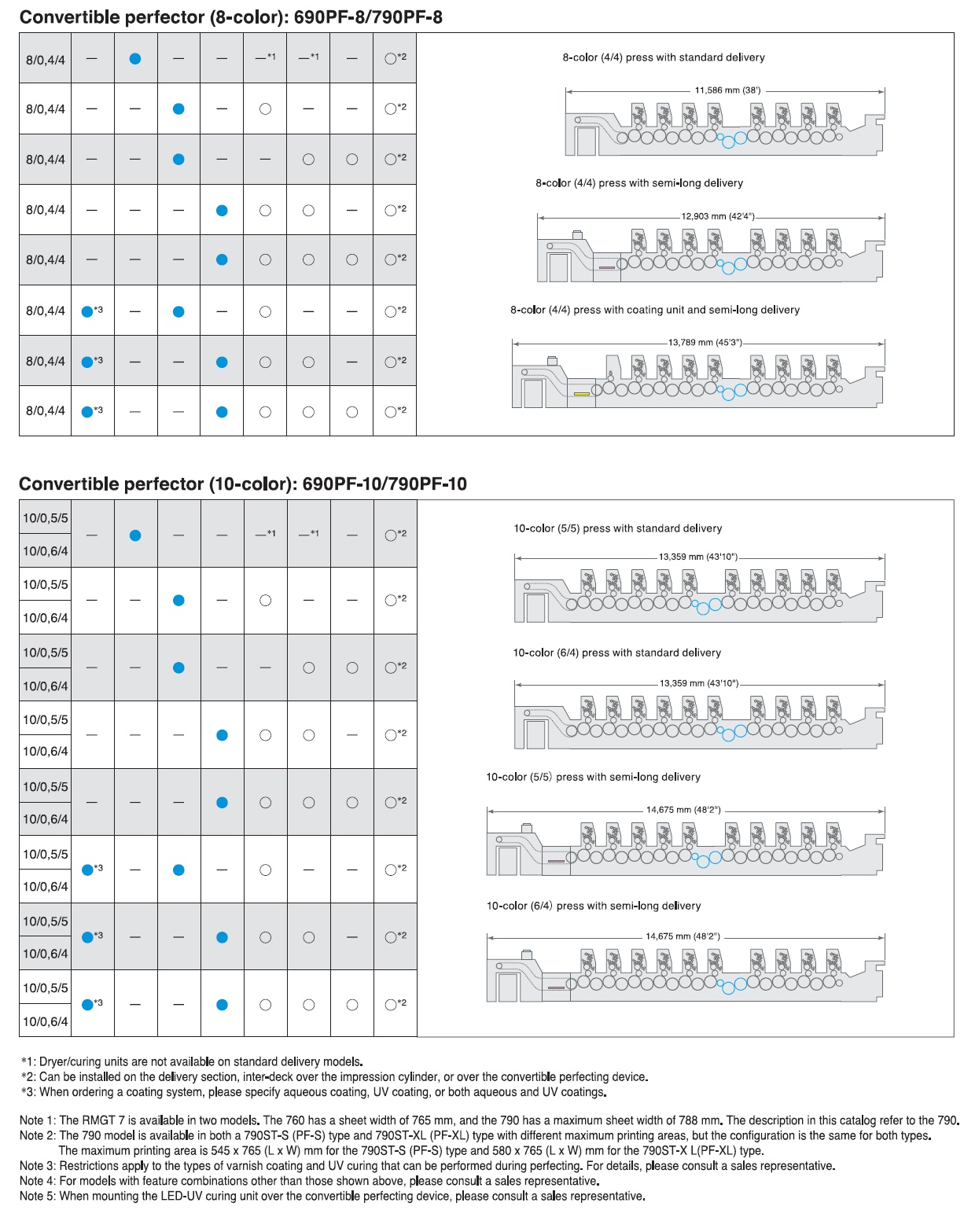

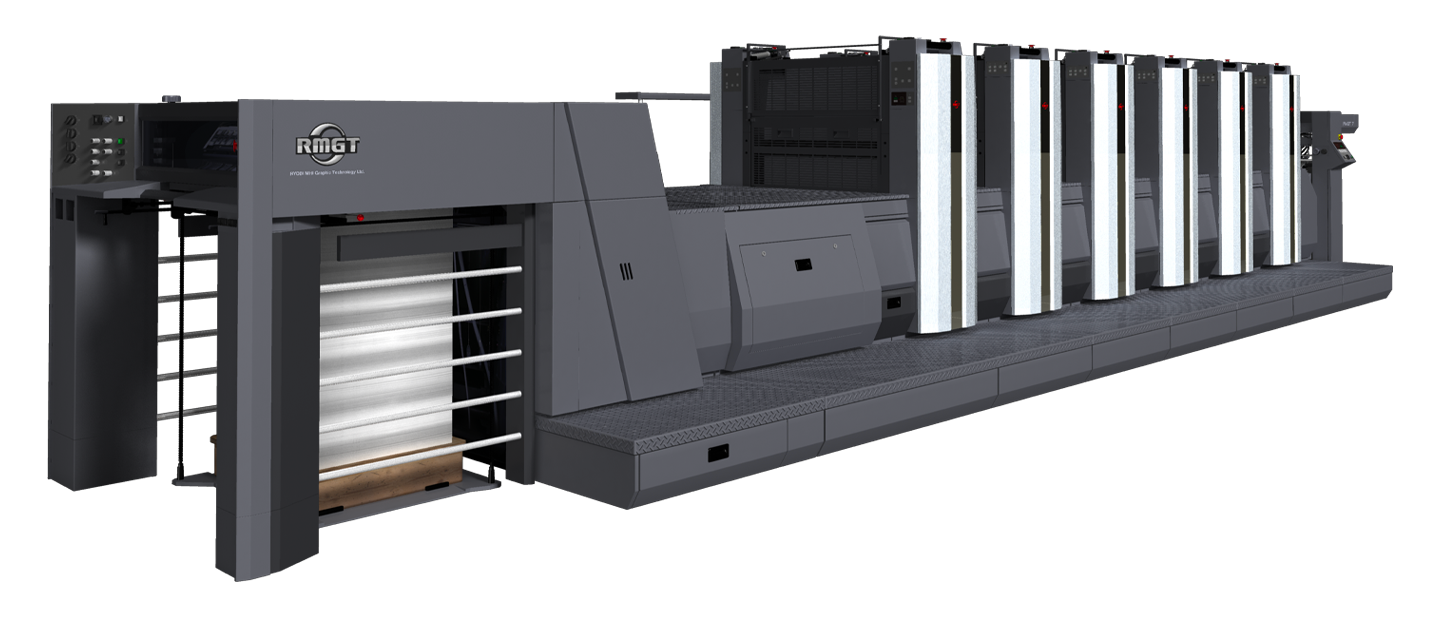

The 790 models can be configured according to customer needs, providing the optimum printing environment for increasing productivity and profitability. A highly reliable mechanism featuring the latest technologies and advanced automation devices, combined with a digital-controlled printing control system, ensures high-speed, high-quality printing.

- Easily handles 8-up printing of B5 size.

- Double-diameter transfer cylinder for stable sheet transport

- Program inking, automatic plate changing system, various preset devices, and other automation systems significantly shorten make-ready.

- Inline printing control of printing sheets including a quality inspection function, a printing density tracking function and an automatic register adjustment function is available with PQS-D (option).

- Continuous printing of multiple short-run work without sampling printed sheets is possible with Smart Assist Printing function (option).

- Incorporating V-type feeder, the same high performance feeder as RMGT 10 series

- Fully automatic convertible perfecting device capable of one-pass perfecting

- Thick cardboard specification model handles sheet thicknesses up to 0.8 mm (option).

- An IR, UV, or LED-UV curing unit can be installed at the delivery section (option).

Case History in Italy

RMGT 790ST-5 installed to Tipografia Senesi in Italy

The 1st new generation RMGT offset machine has finally arrived (and has already gone into production). This is the 10° machine sold to this customer during the years from our company... [read more]

The 1st new generation RMGT offset machine has finally arrived (and has already gone into production). This is the 10° machine sold to this customer during the years from our company... [read more]

SHEETFED OFFSET

SHEETFED OFFSET DIGITAL PRINTING

DIGITAL PRINTING PAPER CUTTERS

PAPER CUTTERS Pile Turners

Pile Turners GIETZ

GIETZ AGV

AGV LED UV

LED UV QUALITY CONTROL

QUALITY CONTROL ROLLERS

ROLLERS MITSUBISHI

MITSUBISHI RYOBI

RYOBI RMGT

RMGT SHEETFED OFFSET

SHEETFED OFFSET CUTTING

CUTTING FOLDING

FOLDING SADDLESTITCHING

SADDLESTITCHING BINDING

BINDING DIE CUTTING

DIE CUTTING VARIOUS

VARIOUS