UPGRADE FOR YOUR OFFSET PRINTING MACHINE

Our technical support is able to offer upgrades for RGMT offset presses for retrofit on site with various devices, software, etc., to update the functionality and performance of MITSUBISHI and RYOBI machines such as the new RMGT models. We can manage upgrades of various systems even in all multi-brand used offset printing machines.

SHEETFED OFFSET

SHEETFED OFFSET DIGITAL PRINTING

DIGITAL PRINTING PAPER CUTTERS

PAPER CUTTERS Pile Turners

Pile Turners GIETZ

GIETZ AGV

AGV LED UV

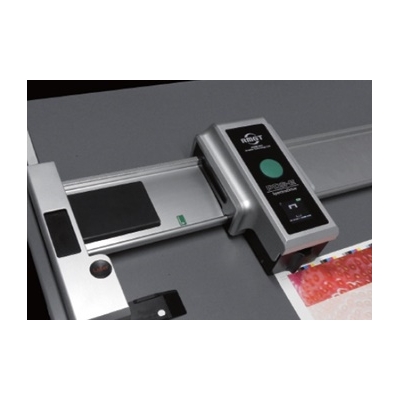

LED UV QUALITY CONTROL

QUALITY CONTROL ROLLERS

ROLLERS MITSUBISHI

MITSUBISHI RYOBI

RYOBI RMGT

RMGT SHEETFED OFFSET

SHEETFED OFFSET CUTTING

CUTTING FOLDING

FOLDING SADDLESTITCHING

SADDLESTITCHING BINDING

BINDING DIE CUTTING

DIE CUTTING VARIOUS

VARIOUS