Latest-generation POLAR 115 X paper cutter at Print In Italy Srl

Published: 2019-12-13 - Categories: INSTALLATIONS , WGM

The story of this beautiful company from Casarano (LE) began in 1981 when the founder Giovanni Perruccio, stimulated by his love for the printing industry, decided to invest in a group of people, the company's real lifeblood. With the premature death of the founder, the company's activities are divided between the two heirs.

Massimo Perruccio with the company name Perruccio srl is exclusively dedicated to printing labels on reels. Barbara Perruccio with the company name Print In Italy Srl takes over the offset printing dedicated to paper and related products.

The production ranges from labels and labels to reels, on different supports with various printing solutions; from offset to screen printing, from hot and cold printing to embossing, from digital to flexo for the most disparate sectors: OENOLOGY AND OIL SEA, FOOD, BEER AND SPIRITS, COSMETICS, DETERGENCE AND CHEMISTRY).

Special materials and processes are also used, such as: BARRIERATE PLUS CARDS, HEAT-SENSING PAPERS, WOODEN CARDS, COUPLED CARDS AND MATERIALS, TRIPLEX ALUMINUM, SPECIAL DIE CUTTERS, MYLUXURY GOLD AND MOLDED SILVER, RELIEF AND DRY-BASED SILVER PRINTING TACTILE INK, HOT AND COLD PRINTING, GLITTER - THERMOCHROMIC INKS, FLUORESCENT INKS, SCENTED INKS, PLASTIFICATIONS, COLLAR AND CAVALLINI CARDS, OPEN AND CLOSE SAVES FRESHNESS, ANTI-BURNING SEALS FOR SPECIAL USES, ULTRA TRANSPARENT 'NO LABEL LOOK'.

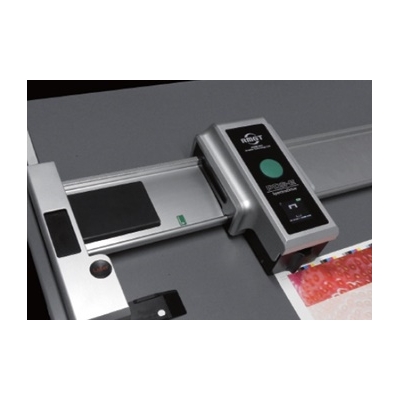

We are proud to have provided a fantastic latest generation POLAR 115 X paper cutter. The machine is controlled by an ergonomic control panel with display and keyboard that facilitate its use. The cutting sequences can be saved in memory so as to speed up repetitive jobs.

POLAR cutting machines (in the graphics industry also called guillotine or paper cutters) are programmable cutters with hydraulic drive units.

Operators appreciate the simplicity of use while the company appreciates the long life of the machine that does not need complex maintenance. The unique cutting precision is achieved thanks to a robust construction and a direct measurement system.

SHEETFED OFFSET

SHEETFED OFFSET DIGITAL PRINTING

DIGITAL PRINTING PAPER CUTTERS

PAPER CUTTERS Pile Turners

Pile Turners GIETZ

GIETZ AGV

AGV LED UV

LED UV QUALITY CONTROL

QUALITY CONTROL ROLLERS

ROLLERS MITSUBISHI

MITSUBISHI RYOBI

RYOBI RMGT

RMGT SHEETFED OFFSET

SHEETFED OFFSET CUTTING

CUTTING FOLDING

FOLDING SADDLESTITCHING

SADDLESTITCHING BINDING

BINDING DIE CUTTING

DIE CUTTING VARIOUS

VARIOUS