New offset printing machines

We select from the best manufacturers the best printing, pre-press and post-press equipment that allow the modern graphic industries to be competitive in the market, offering qualified technical assistance with direct technicians.

SHEETFED OFFSET

SHEETFED OFFSET DIGITAL PRINTING

DIGITAL PRINTING PAPER CUTTERS

PAPER CUTTERS Pile Turners

Pile Turners GIETZ

GIETZ AGV

AGV LED UV

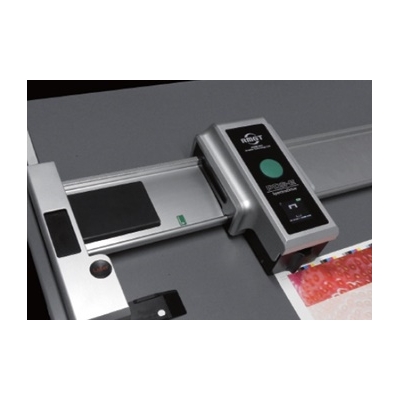

LED UV QUALITY CONTROL

QUALITY CONTROL ROLLERS

ROLLERS MITSUBISHI

MITSUBISHI RYOBI

RYOBI RMGT

RMGT SHEETFED OFFSET

SHEETFED OFFSET CUTTING

CUTTING FOLDING

FOLDING SADDLESTITCHING

SADDLESTITCHING BINDING

BINDING DIE CUTTING

DIE CUTTING VARIOUS

VARIOUS